Innovation, quality and reliability are the foundations of our long-standing family business. Since the company was founded in 1960, we have made many advances in the field of tableting tools and have successfully established the "NOTTER TABLETING TOOLS" brand in the pharmaceutical and food industries. The consistent precision and above-average service life of our tableting tools have always been particularly key to our success and are becoming ever more crucial, especially given today's trend of increasing production and minimizing costs. The forward momentum generated by our company is what drives us to maintain our strategic direction and base our future products on these same foundations.

2023

NOTTER receives the Schwarzer Löwe business award in the Innovation and Sustainability category for its Plasmachrom coating.

2012

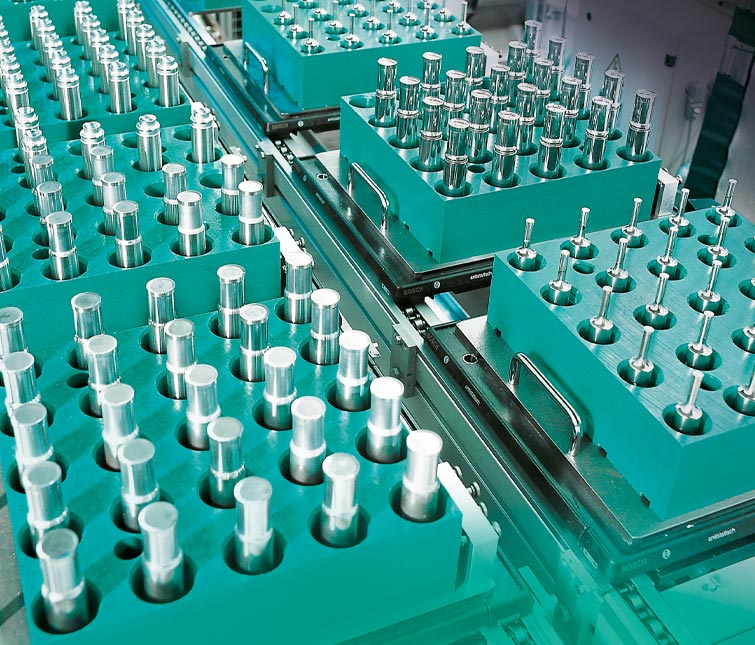

Further innovative tools for tablet production are introduced in the form of the mono multi-tip tool as well as the NOTTER bushes and die segments.

2004

The new building is expanded due to the company's continuing success. The extension doubles the production area.

2000

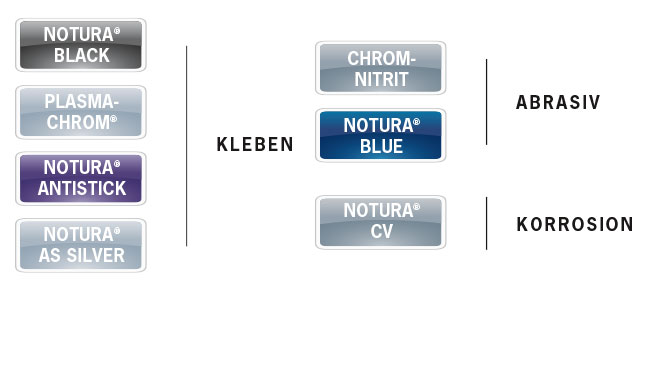

The Notura® Pharm, Black, CRN, Antistick, AS Silver, Blue and CV coatings are all introduced.

1998

NOTTER launches the patented Plasmachrom® coating. The great strength of this coating lies in its ability to successfully counteract adhesion and sticking.

1996

The old factory building, which Otto Scheible looked back on proudly throughout his life, is given a new purpose. Under the management of Manfred Notter, it will now be home to NOTTER Surface Technology, and innovative surface coatings will be developed there.

At this time, a subsidiary is also founded in Japan to take over sales in Japan and Asia. [Image: Adolf Notter (front left), Morimoto senior (front right), Manfred Notter (rear left)]

1994

In the years that follow, the company grows and production capacity is no longer sufficient to meet demand. In 1994, a newly built, large, modern building on the In den Erlen industrial estate in Ölbronn solves the problem. All the different parts of the company gradually relocate to the new headquarters.

1994

NOTTER Snap-Tab®

The two sons of the company director combine their ingenuity with the knowledge they have gained during their studies in order to develop innovative products, such as Snap-Tab®, which ensures that tablets break in precisely the right place, so that each part of the tablet contains the right dose of the active ingredients.

1993

Adolf Notter's sons Klaus and Manfred join the company. [Image (2010): Adolf Notter, Manfred Notter, Klaus Notter (from left to right)]

1989

Otto Scheible passes away at the age of 82 following an illness.

1985

NOTTER launches replaceable tools that do not require die alignment, and offers them as standard.

1980

"Zorn und Scheible Werkzeugbau" becomes "NOTTER GmbH Werkzeugbau." After the change of name, the company grows rapidly and soon employs 40nbspworkers. By way of comparison, the company employed seven people in 1973. The company makes a name for itself in the pharmaceutical industry through innovation and creativity.

1972

After Otto Scheible suffers a long and serious illness, mechanical engineer Adolf Notter, who is also married to Scheible's daughter Beate, takes over the company.

The illness weakened the company as well as its owner, so production has to be completely restructured. From now on, the company will only produce tableting tools for the pharmaceutical and chemical industries.

1975

In the years that follow, the company gets back on the road to success under Adolf Notter, and the old production hall is extended many times.

1962

After 17 years of makeshift production in a barn, the new production hall at 3–5 Lückenbronnstraße in Ölbronn is opened.

1945

Accompanying label from the company Zorn & Scheible, one of the few remnants of the Pforzheim company from 1939

At the end of the difficult post-war years, the company is growing again and is able to hire new workers.

1945

The Deckel FP1 milling machine rescued from the fire and repaired by Scheible himself – the foundation for the new start in Ölbronn (year of manufacture: 1935–1937)

1945

On February 23, 1945, the company building is destroyed in the course of the Allied air raid on Pforzheim, which claims almost 18,000 victims.

On the same day, Otto Scheible flees with his wife and daughter to his old hometown of Ölbronn. From the wreckage, he rescues a milling machine, which he transports from Pforzheim to Ölbronn on an oxcart. There, he repairs the machine himself in a barn, which from then on serves him as a production facility for the makeshift manufacture of products – including some that fall outside traditional toolmaking.

1939

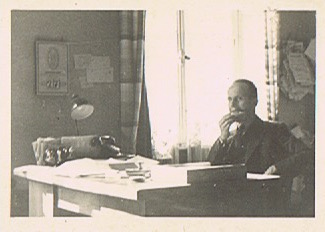

Otto Scheible having a snack during the breakfast break in around 1939

The company benefits from the flourishing Pforzheim jewelry and tool industry in the 1930s and is able to hire additional workers. Then comes the Second World War and, like the rest of the industry, the company has to switch to producing goods essential to the war effort.

1929

In Pforzheim, in the late 1920s, Ludwig Zorn founds a workshop where he will produce tools for the local jewelry industry.

Around this time, Otto Scheible from Ölbronn begins training as a toolmaker at the small company and meets Ludwig Zorn's daughter, whom he will later marry.

When the company founder Ludwig Zorn has a tragic motorcycle accident, Otto Scheible becomes master toolmaker and takes over the business, which continues initially as "L. Zorn Witwe" and later as "Zorn & Scheible Werkzeugbau."